Choosing between island and L-shape layouts impacts safety and workflow in your workspace. An island promotes openness and interaction but requires careful management of hazard zones and pathways to prevent clutter and congestion. An L-shape layout offers a compact, enclosed feel, making it easier to control access and reduce walking distances. Proper equipment placement, lighting, and signage are essential in both setups. Keep exploring to discover how to optimize safety with each layout type.

Key Takeaways

- Island layouts promote open pathways, reducing congestion and facilitating emergency access, while L-shape layouts require careful obstacle management at corners.

- Proper equipment placement and signage are crucial in both layouts to prevent obstructions and ensure clear evacuation routes.

- Ergonomic furniture and adequate lighting enhance safety and reduce strain regardless of layout type.

- Clear traffic lanes and designated pathways minimize crossing points and collisions in both workspace configurations.

- Regular safety reviews and hazard zone markings are essential to maintain safety standards in island and L-shape layouts.

Overview of Workspace Layouts: Island vs. L-Shape

When choosing between island and L-shape workspace layouts, it’s important to understand their core differences. An island layout features a central workspace surrounded by open space on all sides, making it ideal for collaborative assembly lines and flexible tasks. Its aesthetic design promotes openness and modern appeal, encouraging interaction among team members. In contrast, an L-shape layout arranges workstations along two perpendicular walls, creating a compact and efficient workspace. This design suits tasks requiring focused attention and minimizes walking distance. Both layouts influence workflow and visual appeal, but your choice depends on your specific needs. If you prioritize a sleek, open aesthetic with versatile assembly line setups, an island layout might be best. For efficient use of space with a more enclosed feel, an L-shape layout offers a practical alternative. Additionally, considering room layout principles can help optimize safety and functionality in your workspace design.

Safety Considerations in Open-Plan Workspaces

Open-plan workspaces, like island layouts, foster collaboration but also introduce specific safety challenges. You need to prioritize ergonomic comfort to prevent strain and injury, guaranteeing your workstation setup supports proper posture. Acoustic privacy is essential to reduce distractions and maintain focus, but it also affects safety by minimizing noise-related hazards. Consider these safety tips:

Prioritize ergonomic comfort and acoustic privacy to create a safe, focused, and collaborative workspace.

- Arrange furniture to prevent tripping hazards

- Use ergonomic furniture to support comfort and health

- Incorporate sound-absorbing materials for acoustic privacy

- Keep walkways clear of clutter

- Ensure proper lighting to avoid accidents

- Be aware of Glycolic Acid Benefits that can impact skin health, especially if employees are exposed to skincare products in shared spaces

Balancing collaboration with safety requires attention to ergonomic comfort and acoustic privacy, creating a workspace that’s both productive and secure.

Emergency Egress and Accessibility Challenges

Ensuring clear emergency egress and accessibility in island and L-shape layouts can be challenging due to their open and often complex configurations. You need to carefully plan fire escape routes that provide direct, unobstructed paths to exits, regardless of workspace arrangement. Proper emergency signage is essential to guide occupants quickly and safely during an evacuation. In island layouts, signs should be visible from all angles and clearly point toward exits, avoiding confusion. L-shape layouts require strategic placement of fire escape routes to prevent bottlenecks. Regularly reviewing and updating signage and escape plans guarantees they remain effective. Your goal is to minimize delays and hazards during emergencies, making sure everyone can evacuate swiftly and safely, no matter the workspace’s design. User control over signage visibility and placement can significantly impact evacuation efficiency.

Navigating Traffic Flow and Worker Movement

You need clear pathways to keep traffic flowing smoothly and avoid bottlenecks. Minimizing cross-traffic risks helps prevent accidents and keeps workers safe. Managing worker zones effectively guarantees everyone moves efficiently without interference. Incorporating proper signage and projector placement strategies can further enhance safety and operational flow.

Clear Pathways Essential

Maintaining clear pathways is essential for smooth traffic flow and worker safety in both island and L-shape layouts. Well-defined pathways prevent congestion and reduce accidents, ensuring efficient operations. To achieve this, consider:

- Keeping decorative elements minimal along main routes

- Prioritizing functional design over purely aesthetic considerations

- Clearly marking walkways and traffic lanes

- Avoiding clutter that obstructs movement

- Using signage to guide traffic and workers effectively

- Incorporating digital literacy programs to promote playful communication and foster a safe, engaging environment for all users.

Minimize Cross-traffic Risks

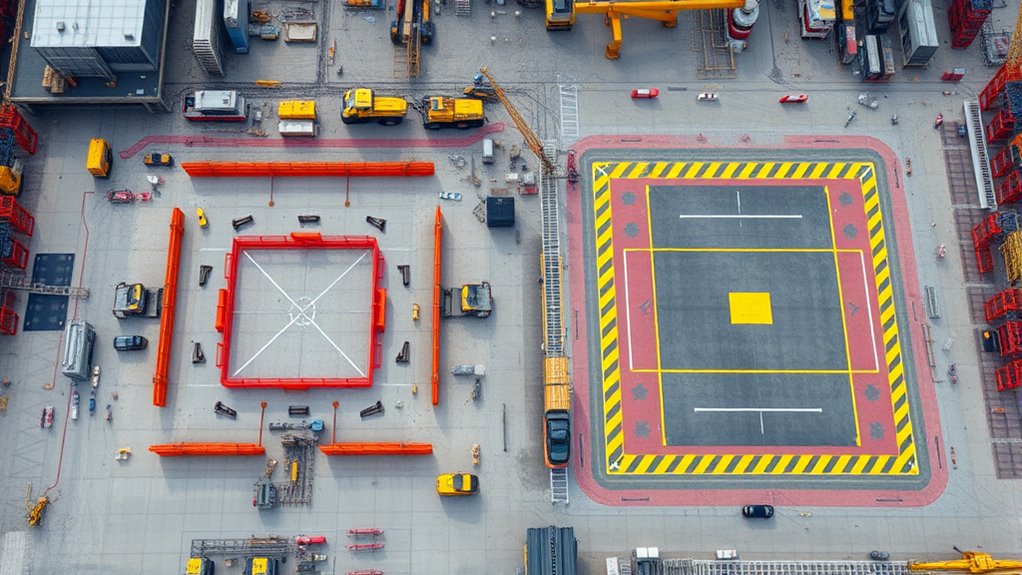

To minimize cross-traffic risks, it’s essential to design traffic flow that directs workers and vehicles along separate, well-defined routes. Clear pathways reduce congestion and prevent accidents, enhancing ergonomic comfort and aesthetic appeal. Use signage and physical barriers to guide movement, ensuring critical zones stay distinct. This setup streamlines operations and keeps everyone safe. Consider creating one-way aisles or dedicated entry and exit points, minimizing crossing paths. Properly marked zones help workers stay focused and reduce fatigue. Below is a visual guide to effective traffic management:

| Route Type | Purpose | Design Tip |

|---|---|---|

| Pedestrian paths | Safe worker movement | Use contrasting flooring |

| Vehicle lanes | Material transport | Keep clear of worker zones |

| Crosswalks | Transition areas | Use visible markings |

| Loading zones | Material handling | Separate from main traffic |

| Emergency exits | Safety routes | Keep unobstructed |

Additionally, understanding the neurotransmitters involved in sleep regulation can help optimize shift schedules and improve overall safety during work operations.

Manage Worker Zones

How can you guarantee worker zones effectively navigate traffic flow and movement within the layout? Proper worker zone allocation is key. Clearly define zones for different tasks and ensure pathways are unobstructed. Use safety signage placement strategically to guide workers and alert them to hazards. To optimize movement, consider these tips:

- Designate separate entry and exit points for each zone

- Use visual cues like floor markings and signs for direction

- Limit worker zones to reduce congestion

- Regularly review traffic patterns and adjust zones as needed

- Communicate zone boundaries clearly during training

- Incorporate yoga techniques such as mindfulness and focused breathing to improve worker concentration and reduce accidents during movement.

Hazard Zones and Obstacle Management

Have you considered how hazard zones and obstacle management differ between island and L-shape layouts? In an island layout, hazard zones are more centralized, requiring clear boundaries around key areas to prevent accidents. Obstacle management involves keeping pathways open and free of clutter, especially around the perimeter. Conversely, L-shape layouts create hazard zones along the inner corners and connecting points, which can be tricky to monitor. You need to make certain obstacles are minimized in these tight spaces to reduce collision risks. Properly managing obstacle placement and clearly marking hazard zones are essential in both layouts. By understanding these differences, you can better design your workspace to enhance safety, reduce accidents, and ensure smooth operations across various layout types. Additionally, implementing vertical storage solutions can help optimize space and keep pathways clear, further reducing hazards.

Equipment Placement and Safety Risks

You need to guarantee equipment is placed so that access paths remain clear and unobstructed, preventing accidents and delays. Overcrowding equipment can create safety hazards and make emergency responses more difficult. Careful planning helps minimize these risks and keeps your workspace safe. Incorporating stress management techniques into your safety protocols can further enhance overall safety awareness.

Access Path Obstructions

Access path obstructions can considerably impact safety and workflow efficiency, especially when equipment placement blocks essential routes. When pathways are cluttered or blocked, congestion issues increase, slowing down movement and risking accidents. Clear signage is crucial to guide staff and visitors, but obstructions can obscure signage clarity, leading to confusion. To prevent these issues, consider these points:

- Keep pathways free of unnecessary equipment and supplies

- Regularly review and adjust equipment placement

- Ensure signage remains visible and unobstructed

- Design layouts that prioritize direct routes

- Monitor for congestion points during peak times

- Understanding Gold IRA regulations can help ensure compliance with safety standards in storage facilities.

Equipment Overcrowding Risks

Overcrowding equipment in confined spaces can considerably increase safety hazards and reduce operational efficiency. Equipment overcrowding leads to workspace congestion, making it difficult to move safely and access tools quickly. When equipment is placed too close together, workers risk tripping, bumping into machinery, or causing accidental displacements. This cluttered environment can also hinder emergency responses, delaying evacuation or rescue efforts. Additionally, workspace congestion raises the likelihood of equipment overheating or malfunctioning due to poor airflow. To prevent these risks, ensure proper spacing between machines, organize equipment logically, and maintain clear pathways. By managing equipment placement effectively, you reduce safety hazards and improve workflow, creating a safer, more efficient work environment.

Lighting and Visibility Concerns

Have you ever noticed how the layout of a kitchen impacts its lighting and visibility? Both Island and L-shape designs influence how well you see and work. To guarantee safety, focus on proper ambient illumination and task lighting.

Consider these points:

- Position ambient lighting to evenly brighten the entire space

- Use task lighting directly over work areas like sinks and countertops

- Avoid shadows caused by cabinets or islands blocking light

- Opt for adjustable fixtures to customize brightness

- Ensure lighting is sufficient for all cooking and prep zones

Good lighting reduces accidents and makes your workspace safer. Proper visibility is essential, especially in busy kitchens, regardless of the layout.

Best Practices for Layout Optimization and Safety

To optimize your kitchen layout and guarantee safety, it’s essential to follow best practices that promote efficient workflow and minimize hazards. Focus on ergonomic design by arranging work zones to reduce unnecessary movement and strain. Position frequently used appliances and tools within easy reach, and maintain clear pathways to prevent trips and collisions. Incorporate noise control measures, like sound-absorbing materials or barriers, to reduce distractions and stress, creating a safer environment. Make certain proper lighting for visibility and avoid clutter that could lead to accidents. Regularly evaluate your layout, making adjustments to enhance safety and comfort. Prioritizing ergonomic principles and noise control not only improves safety but also boosts productivity and overall kitchen functionality.

Frequently Asked Questions

How Do Layout Choices Impact Long-Term Worker Productivity?

Your layout choices directly impact long-term worker productivity by promoting ergonomic design and lighting optimization. An ergonomic setup reduces strain and fatigue, helping workers stay focused and efficient. Proper lighting minimizes eye strain and boosts alertness, ensuring consistent performance. By carefully selecting your layout, you create a comfortable environment that encourages sustained productivity and minimizes health issues, ultimately leading to happier, healthier, and more productive employees over time.

What Are the Cost Implications of Switching Between Layouts?

Switching layouts involves a thorough cost analysis to understand expenses like renovation, furniture, and equipment. You’ll also want to contemplate layout flexibility, which affects future adaptability and potential costs. While transitioning may incur initial costs, it can improve efficiency and worker safety long-term. Planning carefully guarantees you balance short-term expenses with long-term benefits, making the switch worthwhile without unexpected financial burdens.

How Do Layouts Accommodate Future Workspace Expansions?

Did you know that 78% of companies plan for future workspace changes? You can accommodate expansions with modular adaptability features in your layout, allowing you to easily reconfigure or add stations. Both island and L-shape layouts support space optimization, but islands often provide more flexibility for growth. By choosing adaptable furniture and strategic design, you guarantee your workspace remains functional and efficient as your team and needs grow.

Are There Industry-Specific Safety Standards for These Layouts?

Yes, industry-specific safety standards apply to both island and L-shape layouts, ensuring regulatory compliance and worker safety. You need to contemplate ergonomic considerations, like proper workstation heights and clear pathways, to prevent injuries. Follow guidelines from organizations like OSHA or ANSI, which often tailor standards based on industry needs. Regular safety audits and staff training help maintain compliance and adapt layouts for evolving safety requirements.

How Do Layouts Influence Worker Collaboration and Communication?

Your layout directly impacts worker collaboration and communication by shaping visual communication and spatial efficiency. An open island layout encourages face-to-face interactions and quick sharing of ideas, enhancing teamwork. Conversely, an L-shape layout can create defined zones that might hinder immediate communication but improve focus. Consider how your space facilitates visibility and movement, ensuring your team stays connected and efficient while maintaining safety standards.

Conclusion

Picture your workspace as a well-orchestrated dance floor, where every move is smooth and safe. Choosing between island and L-shape layouts is like selecting the perfect choreography—each has its rhythm and flow. Prioritize clear pathways, well-placed equipment, and good lighting to keep your team moving confidently. When safety becomes your guiding step, your workspace transforms into a vibrant, efficient environment where everyone can thrive without stumbling over hazards.