Infrared searing zones use focused radiation to deliver intense, even heat directly to food or surfaces, speeding up cooking and enhancing flavor. Understanding safe operation is vital—strictly stay within designated safety zones and avoid hazard areas with high heat. The technology reduces flare-ups and burns, but improper use can cause injuries. If you follow proper safety tips and practices, you’ll protect yourself and others. Keep exploring to learn how to maximize safety with infrared searing zones.

Key Takeaways

- Infrared searing zones deliver intense, focused heat for faster cooking while minimizing heat loss and hotspots.

- Safety zones are designated safe areas; hazard zones involve high heat requiring protective measures.

- Proper protective gear, such as infrared glasses and heat-resistant gloves, is essential for safe operation.

- Recognizing and respecting hazard boundaries prevents burns and injuries from infrared radiation.

- Emergency procedures include cooling burns with water, covering wounds, and calling for medical help promptly.

Understanding Infrared Technology and Its Applications

Infrared technology plays a crucial role in various modern applications by harnessing the power of electromagnetic radiation invisible to the naked eye. You’ll find infrared applications across industries like healthcare, security, and manufacturing, where precise heat detection and imaging are essential. This technology integration allows devices to detect heat signatures, monitor temperatures, and even enable remote controls. Infrared sensors and cameras work seamlessly with other systems, providing real-time data that helps improve safety, efficiency, and accuracy. By understanding how infrared technology functions, you can better appreciate its versatility and importance in daily life. Whether in thermal imaging or automated systems, infrared applications continue to advance, making processes safer, faster, and more effective. Additionally, advancements in infrared sensing improve the accuracy and reliability of these systems, further enhancing safety and operational effectiveness.

What Are Infrared Searing Zones?

Infrared searing zones are specific areas on a grill or oven where infrared technology delivers intense heat quickly. They work by emitting infrared rays that directly transfer heat to your food, resulting in faster cooking. The benefits include improved searing, better flavor retention, and more efficient cooking processes. To ensure safety and optimal performance, it’s important to select vetted products that meet high standards for effectiveness and safety.

How They Work

Infrared searing zones work by directly emitting infrared radiation that heats the surface of your food rapidly and evenly. This radiation is absorbed quickly because of its high thermal conductivity, allowing heat to penetrate the food’s surface efficiently. Unlike traditional methods, infrared zones minimize heat dissipation into surrounding areas, focusing energy where it’s needed most. This targeted heating creates a sear that locks in juices and flavors while delivering a crisp exterior. Because infrared radiation heats objects directly, it reduces overall cooking time and ensures consistent results. The design ensures that heat transfer is swift and controlled, preventing hotspots and uneven cooking. Additionally, food safety is enhanced as the rapid heating reduces the risk of bacteria survival on surfaces. By understanding how infrared searing zones operate, you can harness their power to achieve perfectly seared, flavorful dishes every time.

Benefits of Infrared

One of the main advantages of infrared searing zones is their ability to heat food quickly and efficiently, saving you time in the kitchen. Infrared technology provides superior heat efficiency, ensuring your food cooks evenly and preserves moisture. Plus, infrared comfort means you won’t experience cold spots or uneven heating. This focused heat allows for rapid searing, locking in flavor and juices. The benefits extend beyond cooking speed, offering better temperature control and energy savings. You’ll enjoy consistent results with less effort. Infrared searing zones also reduce flare-ups and smoke, making grilling safer and cleaner. To maintain optimal performance, ensure the doorbell is within Wi-Fi range and keep the device clean and well-maintained. Overall, they enhance your grilling experience by combining quick, even heat with improved safety and energy efficiency.

The Science Behind Infrared Heat Transfer

You might wonder how infrared heat actually works. It involves electromagnetic radiation, specifically within certain wavelengths that efficiently transfer heat. This process includes both direct radiation and conduction, which together create the intense warming effects you experience. AI safety measures are crucial to ensure these technologies are developed responsibly and securely.

Electromagnetic Radiation Spectrum

Understanding the electromagnetic radiation spectrum is essential to grasp how infrared heat transfer works. This spectrum includes a range of waves, from radio waves to gamma rays, with infrared occupying the middle ground. Infrared radiation is what heats objects directly, making it key in infrared heating systems. Infrared sensors detect this radiation for safety and control, ensuring proper operation. Radiation shielding helps prevent unwanted exposure, protecting users from excessive heat or radiation. Recognizing these components allows you to understand how infrared zones deliver targeted warmth safely. Additionally, attention plays a crucial role in detecting subtle changes in heat levels, ensuring precise regulation of infrared systems.

Infrared Wavelengths’ Role

Infrared wavelengths determine how heat is transferred and absorbed by objects, making them essential to effective infrared heating. Different infrared wavelengths penetrate materials at varying depths, influencing how heat absorption occurs. Shorter wavelengths tend to be absorbed quickly on the surface, providing rapid heating, while longer wavelengths penetrate deeper, offering sustained warmth. Your choice of infrared wavelengths impacts efficiency and safety, as ideal wavelengths maximize heat transfer with minimal energy waste. When infrared radiation matches an object’s natural absorption spectrum, heat transfer is more efficient, reducing energy costs and hot spots. Wavelength penetration depth plays a crucial role in customizing infrared heating solutions. By understanding the role of infrared wavelengths, you can better control heat absorption, ensuring consistent, safe, and effective heating in your application.

Direct vs. Conduction Heat

How does infrared heat transfer differ when it occurs through direct radiation versus conduction? With direct radiation, infrared waves emit heat energy that travels through the air and heats objects upon contact, relying on the material’s thermal conductivity. Conduction, however, involves heat transfer through direct touch, where molecules transfer energy from one to another. Infrared heating primarily depends on the object’s ability to conduct heat, making thermal conductivity essential. Additionally, the sensor technology in smart toilets can optimize heat delivery by adjusting based on detected usage and temperature preferences.

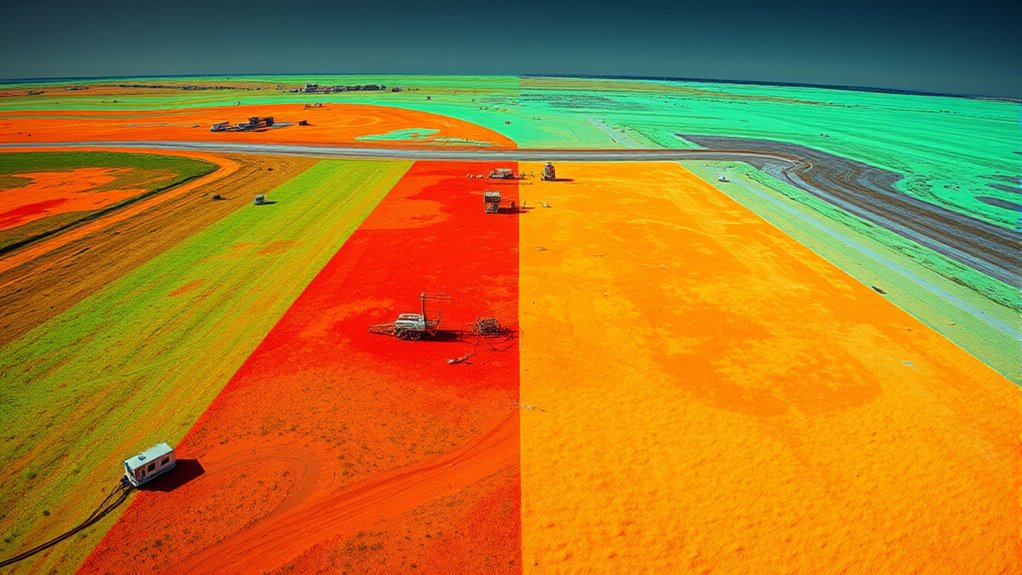

Differentiating Between Safety Zones and Hazard Zones

Distinguishing between safety zones and hazard zones is essential when working with infrared searing equipment, as it directly impacts your safety. A safety zone is the designated area where you can operate the equipment safely, usually marked to prevent accidental entry. In contrast, a hazard area is where the infrared heat is intense enough to cause burns or other injuries. You must stay within the safety zone to avoid exposure to harmful radiation and excess heat. Recognizing these boundaries helps prevent accidents and ensures safe operation. Always respect the designated safety zone and avoid venturing into the hazard area unless equipped with proper protective gear. Clear demarcation and awareness of these zones are key to maintaining a safe working environment around infrared searing equipment.

Practical Tips for Safe Use of Infrared Searing Zones

To guarantee safe use of infrared searing zones, always familiarize yourself with the designated safety and hazard areas before beginning work. Proper infrared safety practices help minimize risks associated with heat exposure. Being aware of your surroundings and layout can further help prevent accidental contact with hot surfaces.

Common Misconceptions and Myths Debunked

Many people assume that infrared searing zones are completely safe because they rely on high-tech equipment and controlled environments. However, this is a common myth that needs myth elimination. Infrared radiation can cause burns if safety guidelines aren’t followed. Misconceptions about its safety often lead to risky behaviors. Additionally, understanding cybersecurity vulnerabilities related to high-tech equipment emphasizes the importance of strict safety protocols. Understanding these misconceptions helps you stay safe. Always adhere to safety guidelines, and don’t assume safety is guaranteed just because technology is involved. Myth elimination is key to preventing accidents.

Emergency Procedures and First Aid for Infrared-Related Incidents

When an infrared-related incident occurs, acting quickly and correctly can considerably reduce the severity of injuries. Your first priority is ensuring fire safety and initiating an effective emergency response. Immediately move the affected person to a cool area and remove any contaminated clothing. Do not apply ice directly to burns; instead, run cool, not cold, water over the area to prevent further tissue damage. Call emergency services if burns are severe or cover a large area. Keep the person calm and monitor their breathing. Use a clean, sterile dressing to cover burns if available. Remember, quick, appropriate action minimizes injury impact and prevents escalation.

- Assess the scene for safety before approaching

- Call emergency responders promptly

- Cool burns with running water for at least 10 minutes

- Cover burns with sterile, non-stick dressings

- Stay calm and reassure the injured person

Best Practices for Outdoor and Professional Safety

Ensuring safety during outdoor and professional infrared operations requires adherence to specific best practices that minimize risk. When working with infrared applications, always follow established safety protocols to protect yourself and others. Wear appropriate protective gear, including infrared-rated glasses and heat-resistant gloves, to prevent burns and eye damage. Conduct thorough risk assessments before starting any project, and ensure that equipment is properly maintained. Keep a safe distance from searing zones and clearly mark hazardous areas to alert colleagues. Stay informed about the equipment’s safety features and limitations. Regularly review safety procedures, and never bypass safety measures. By following these best practices, you reduce potential hazards and guarantee a safer environment for everyone involved in infrared applications.

Frequently Asked Questions

How Long Does Infrared Heat Typically Last in Searing Zones?

Infrared heat in searing zones typically lasts around 20 to 30 minutes, depending on durability lifespan and heat retention. You’ll notice the zone maintains high temperatures during this period, ideal for searing meats. To maximize heat retention, keep the lid closed when not in use, and avoid opening the zone frequently. Proper maintenance guarantees consistent performance, giving you reliable searing results over multiple cooking sessions.

Can Infrared Searing Zones Affect Nearby Electronic Devices?

While infrared searing zones are generally safe, they can cause electromagnetic interference that might impact nearby electronic devices. To prevent issues, guarantee proper device shielding and maintain a safe distance from the heat source. This way, you avoid potential disruptions or damage, allowing your appliances to function smoothly. Remember, a little precaution goes a long way in keeping your tech safe while enjoying ideal searing performance.

Are There Any Health Conditions That Increase Infrared Heat Sensitivity?

Yes, certain health conditions like skin sensitivity, rosacea, or photosensitivity can increase your sensitivity to infrared heat. If you have these conditions, you might experience more discomfort or skin irritation from infrared exposure. It’s important to be aware of your personal health risks and limit exposure if needed. Always consult with a healthcare professional if you’re unsure about how infrared heat could impact your skin or overall health.

What Maintenance Is Required to Ensure Safety in Infrared Zones?

You should regularly check sensor calibration to guarantee infrared zones operate safely. Proper maintenance includes inspecting and replacing protective gear, like gloves and shields, to prevent burns or injuries. Confirm that all safety sensors function correctly, especially before each use, to detect any faults early. Keeping equipment clean and following manufacturer guidelines helps maintain consistent performance, reducing risks and ensuring you stay protected in infrared zones.

How Do Weather Conditions Influence Infrared Searing Zone Safety?

Weather conditions critically influence infrared searing zone safety through temperature fluctuations and weather impact. When temperatures drop, equipment may operate less efficiently, increasing the risk of overheating or malfunction. Conversely, high humidity or rain can affect infrared sensors and cause safety hazards. You should regularly monitor weather forecasts, adjust safety protocols accordingly, and guarantee your equipment is protected against weather impact to maintain safe operation in all conditions.

Conclusion

Now that you understand how infrared searing zones work and the safety measures to keep in mind, you’re better equipped to use this technology responsibly. Think of these zones as a double-edged sword—powerful but needing respect. By following best practices, you’ll ensure safety remains your top priority, turning potential hazards into controlled, manageable tools. Stay vigilant, stay safe, and let infrared technology serve you without burning more than you bargained for.